High-Tech Engraving Center Puts Interprint In the Lead

Managing Director Jens Bauer tells how Interprint's new $7 million laser engraving center came to be. Top, Interprint engraved on a roller. |

The 18,000 square-foot center is the only one of its kind in North America that can produce high-quality laser-cut cylinders for printing a wide range of papers for cabinets, flooring, wallpaper, countertops and more.

And with the economic downturn, the expansion has also become the company's symbol of optimism in the struggling global economy.

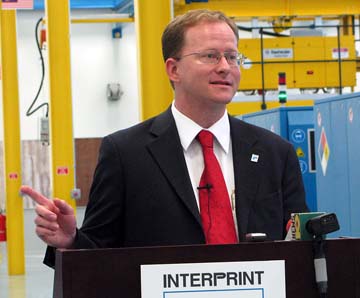

"Our timing could not be better for getting this project off the ground," said William Hines Jr., one of Interprint Pittsfield's two managing directors, at last Friday's formal opening. "Sure you can question why Interprint would continue with such an expansion when the economy is at its lowest point, but as [former CEO] Bill [Hines] Sr. can attest to, we have a long history of impeccable timing ... the startup comes at a time when we need to bring new ideas and projects to the customer and take better control of our destiny."

Hines and co-Managing Director Jens Bauer spoke Friday morning as the specialized machinery continued processing the massive metal cylinders. The ability to engrave the cylinders onsite offered higher quality control, a better product and a new source of revenue by using excess capacity to etch cylinders for other companies, said Bauer.

Todd Lumans, manager of the new center, explains the engraving process. Todd Lumans, manager of the new center, explains the engraving process.  Left, Williams Hines Jr.; right, making sure the chemicals are right to feed the machines. |

Interprint's only other such facility is located in Germany. After seeing the possibilities of the laser engraving system during a trip there in August 2006, not more than a year after its new $23 million manufacturing center opened on Central Berkshire Boulevard, the Pittsfield group pitched placing a second center in the Berkshires.

The attached center broke ground in June last year. It was, said Bauer, "a textbook installation phase now housing the most modern fully automated laster engraving operation in North America."

What makes the cylinders unique is the laser-engraving process. Most cylinders, or rollers, are etched through an electromechanical process in which a diamond stylus cuts the design into the copper roller. Todd Luman, laser engraving manager, likened it to a "woodpecker pecking at a tree."

Laser engraving also cuts into the roller, zinc-plated to better accept the design, but is far less susceptable to variations and far easier to consistently replicate. The cylinders range in size from 2 feet to 8 feet and weigh up to a ton.

The computer-controlled machinery automatically moves the heavy metal from curing to cleaning to etching stations. Once the curing is complete, the final process of etching, cleaning and polishing can take less than two hours; the entire process, less than a day.

The result is a high degree of realism for printed woodgrains, stone and textiles. "As you can imagine, you can achieve a much more detailed and accurate image from using the laser beam than a stylus," said Bauer. "It has excellent printability and, therefore, a superior product for our customers."

It also doesn't need a lot workers: The operation currently employs four with the possibility of adding another shift of up to five. What it means, said Bauer and Hines, is stability and sustainability for the company.

"This puts Interprint miles ahead of the competition, which will help us capture even more of the market," said Hines. "Interprint plans to recover faster than the rest of the industry ... We've just seen our highest order since October of last year. We hope this means an upturn in our business."

|

|

.jpg) |